Isistimu yokusakaza phezulu ye-Cu-OF Rod

Impahla eluhlaza

Ikhwalithi enhle ye-copper cathode iphakanyiswa ukuthi ibe yimpahla eluhlaza yokukhiqiza ukuze kuqinisekiswe umkhiqizo ophezulu wemishini kanye nekhwalithi kagesi.

Iphesenti elithile lethusi eligaywe kabusha lingasetshenziswa futhi. Isikhathi se-de-oxygen esithandweni sizoba side futhi lokho kungase kunciphise impilo yokusebenza yesithando somlilo. Isithando somlilo esincibilika esihlukanisiwe sensimbi yethusi singafakwa ngaphambi kwesithando somlilo ukuze kusetshenziswe ithusi eligaywe kabusha.

Isithando somlilo

Izitini nesihlabathi esakhiwe ngamashaneli ancibilikayo, isithando somlilo sishiselwa ngogesi ngamakhono ahlukahlukene okuncibilika. Amandla okushisa angalungiswa ngesandla noma ngokuzenzakalelayo ukuze kugcinwe ithusi elincibilikisiwe ebangeni lokushisa elilawulwayo. Isimiso sokushisa ngokwaso kanye nomklamo wesakhiwo somlilo owenziwe kahle uvumela ubuningi. ukusetshenziswa kwamandla kanye nokusebenza kahle okuphezulu kakhulu.

Umshini wokusakaza

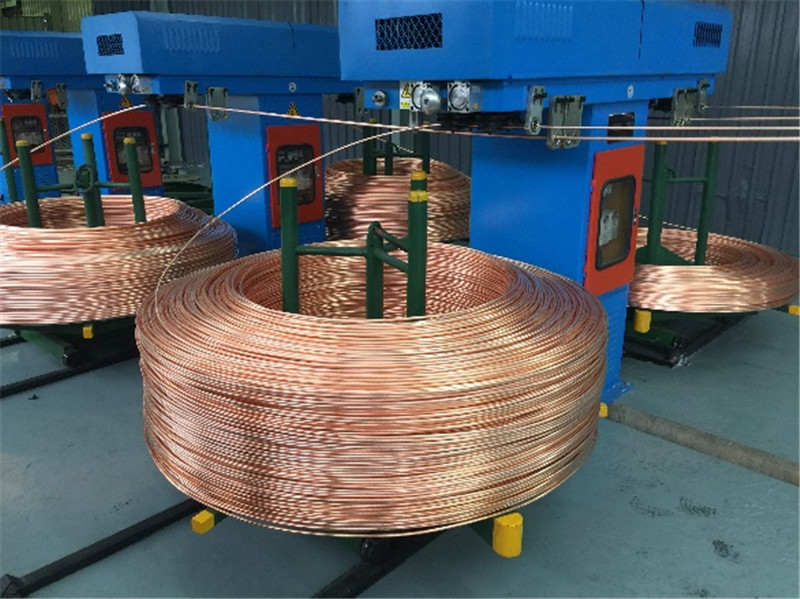

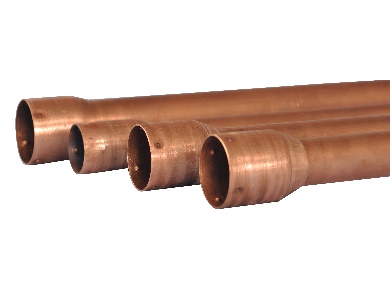

Induku yethusi noma ishubhu ipholiswa futhi iphonswe yi-cooler. Ama-coolers agxilwe kuhlaka lomshini wokuphonsa ngaphezu kwesithando somlilo. Ngesistimu yokushayela i-servomotor, imikhiqizo ekhonjiwe idonsela phezulu ngama-coolers. Umkhiqizo oqinile ngemva kokupholisa uqondiswa kumakhoyili amabili noma umshini wokusika-ubude lapho kufanele kube khona amakhoyili wokugcina noma umkhiqizo wobude.

Umshini ungasebenza ngosayizi ababili abahlukene ngesikhathi esisodwa uma uhlomisa ngamasethi amabili esistimu yokushayela ye-servo. Kulula ukukhiqiza osayizi abahlukene ngokushintsha ama-coolers ahlobene futhi afe.

Uhlolojikelele

Umshini wokuphonsa nesithando somlilo

Idivayisi yokushaja

Umshini wokugcwalisa

Umkhiqizo

Isevisi endaweni

Idatha enkulu yezobuchwepheshe

| Amandla onyaka (Amathani/Unyaka) | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 | 15000 |

| izingcezu ezipholile | 4 | 6 | 8 | 12 | 16 | 20 | 24 | 28 |

| URod Dia. kwe mm | 8,12,17,20,25,30 kanye nesidingo sosayizi okhethekile singenziwa ngezifiso | |||||||

| Ukusetshenziswa kwamandla | 315 kuya ku-350 kwh/ton ukukhiqizwa | |||||||

| Edonsa | I-Servo motor kanye ne-inverter | |||||||

| Iyashaja | Uhlobo okwenziwa ngesandla noma oluzenzakalelayo | |||||||

| Lawula | I-PLC nokusebenza kwesikrini sokuthinta | |||||||

Ukuhlinzekwa kwezingxenye ezisele

I-iron core

Ikhoyili yokungeniswa

Ijakhethi yamanzi okupholisa

Isiteshi se-Fusion

Isitini esimise

Isitini esigcina izinga lokushisa elilula

Ukuhlanganiswa kwe-Crystallizer

Ishubhu yangaphakathi ye-crystallizer

Ishubhu lamanzi le-crystallizer

Ukuhlanganiswa okusheshayo

I-graphite iyafa

Ikesi lokuvikela le-graphite & ulayini

Ingubo yerabha ye-Asbestos

Nano insulation board

I-Cr fiber blanket