Umshini Wokudonsa Ngocingo Lwensimbi-Imishini Esizayo

Izinkokhelo

Inkokhelo eqondile ye-Hydraulic: Iziqu ze-hydraulic vertical rod ezilula ukuthi zilayishwe izintambo futhi ezikwazi ukubola ngokuqhubekayo kwentambo.

Inkokhelo evundlile: Inkokhelo elula eneziqu ezimbili ezisebenzayo ezifanele izintambo zensimbi ye-carbon ephezulu nephansi.Ingalayisha amakhoyili amabili wenduku ebona ukubola kwenduku eqhubekayo.

Inkokhelo engaphezulu: Inkokhelo yohlobo lwe-Passive yamakhoyili ezintambo futhi ifakwe amarola ayisiqondiso ukugwema noma yikuphi ukuphazamiseka kwezintambo.

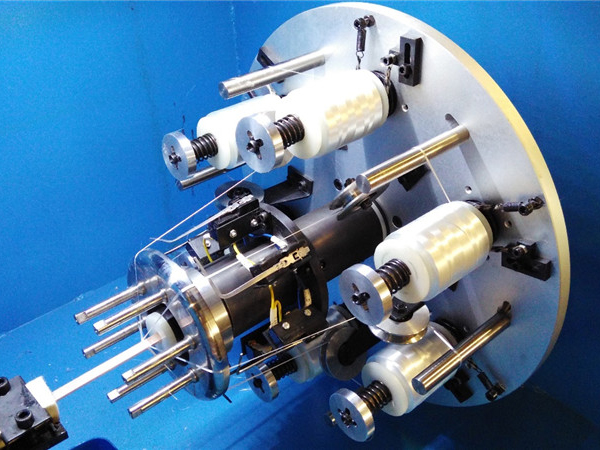

Inkokhelo ye-spool: Inkokhelo eshayelwa yimoto ngokulungiswa kwe-spool yomoya ukuze kucishwe ucingo oluzinzile.

Imishini yokwelapha ngaphambi kwesikhathi

I-wire rod kufanele ihlanzwe ngaphambi kwenqubo yokudonsa.Ngocingo oluphansi lwe-carbon wire, sinomshini wokukhipha isikali onelungelo lobunikazi ozokwanela ukuhlanzwa kwendawo.Ukuze uthole i-carbon wire rod ephezulu, sinomugqa wokukhetha ongenawo umsi wokuhlanza indawo yenduku kahle.Wonke amadivaysi okwelapha ngaphambilini angafakwa kumugqa ngomshini wokudweba noma angasetshenziswa ngokuhlukene.

Izinketho ezitholakalayo

Umshini wokwehlisa i-roller nowokuxubha:

I-sand belt descaler

Umugqa wokukhetha okungenasici

Ukuthatha-ups

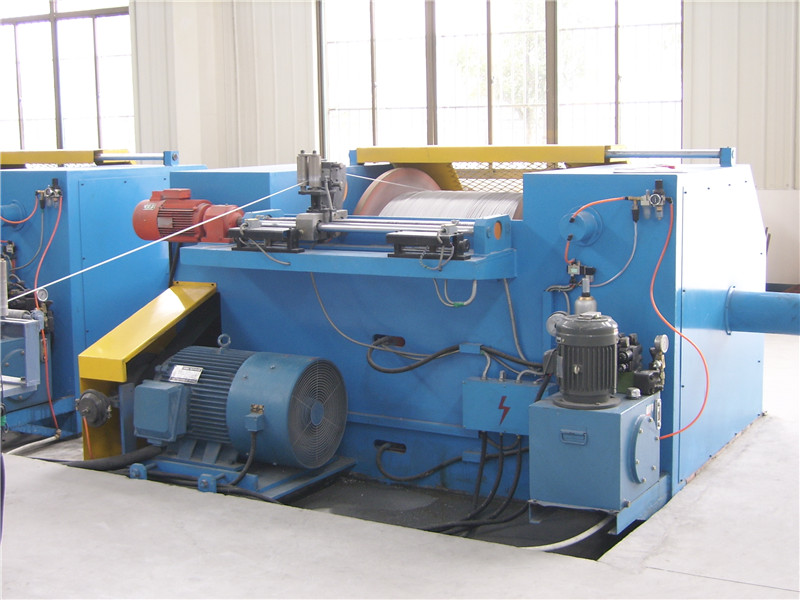

I-Coiler: Singanikeza uchungechunge oluphelele lwe-dead block coiler yosayizi abahlukahlukene bezintambo.Amakhoyili ethu aklanywe njengesakhiwo esiqinile nesivinini esikhulu sokusebenza.Siphinde sibe ne-turntable yamakhoyili esisindo ukuze sihlangabezane nezidingo zamakhasimende.Inzuzo yokusebenzisa ibhulokhi efile yomdwebo ohlelweni lokudweba ngocingo ukususa ibhulokhi eyodwa emshinini wokudweba izintambo.Ukuze kuhlanganiswe intambo yensimbi ye-carbon ephezulu, ikhoyili ihlinzekwa nge-die ne-capstan futhi ifakwe eyakho isistimu yokupholisa.

I-Spooler: Ama-spooler asebenza ngokuhlangene nemishini yokudweba izintambo zensimbi futhi asetshenziselwa ukuthatha izintambo ezidonsayo ukuze ziyiswe kuma-spools aqinile.Sinikeza uchungechunge oluphelele lwama-spooler osayizi abahlukene bezintambo ezidwetshiwe.I-spooler ishayelwa yinjini ehlukene futhi isivinini sokusebenza singavunyelaniswa nomshini wokudweba

Eminye imishini

I-Butt welder:

● High clamping force for izintambo

● Ikhompuyutha encane ilawulwa ukushisela okuzenzakalelayo nenqubo yokuhlanganisa

● Ukulungiswa okulula kwebanga lemihlathi

● Ngeyunithi yokugaya kanye nemisebenzi yokusika

● Amadivayisi e-anneal awo womabili amamodeli ayatholakala

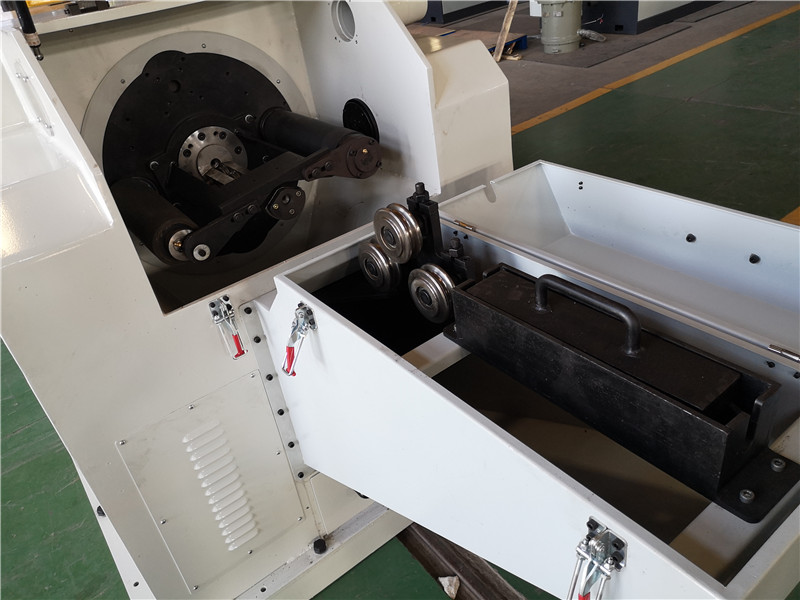

Isikhombi socingo:

● Idivaysi yokudonsa ukuze uphakele i-wire rod ngaphakathi komugqa wokudweba

● Amarola aqinile asebenza isikhathi eside

● Umzimba womshini onyakazayo ukuze usebenze kalula

● Injini enamandla eshayelwa amarola