Imishini Eqhubekayo Yokukhipha

Izinzuzo

I-1, i-plastic deformation yenduku yokudla ngaphansi kwamandla okungqubuzana kanye nezinga lokushisa eliphezulu eliqeda ukukhubazeka kwangaphakathi kwenduku ngokwayo ngokuphelele ukuze kuqinisekiswe imikhiqizo yokugcina esebenza kahle kakhulu yomkhiqizo kanye nokunemba okuphezulu kwe-dimensional.

2, hhayi ukushisisa kwangaphambili noma ukuncishiswa, imikhiqizo yekhwalithi enhle etholwe inqubo ye-extrusion esebenzisa amandla aphansi.

3, ngokuphakelwa kwenduku yosayizi owodwa, umshini ungakhiqiza uhla olubanzi lwemikhiqizo ngokusebenzisa ama-dies ahlukene.

4, wonke umugqa usebenza kalula futhi ngokushesha ngaphandle komsebenzi osindayo noma ukungcola ngesikhathi sokukhipha.

Ukuphakela induku yethusi

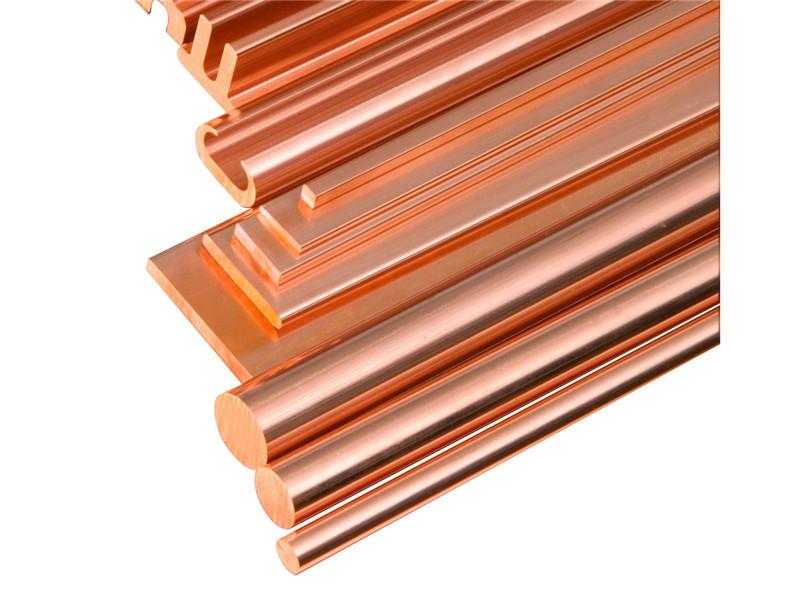

1.Ukwenza izintambo zethusi eziyisicaba, ibhasi encane yethusi kanye nocingo oluyindilinga

| Imodeli | Idatha ye-TLJ300 | I-TLJ 300H |

| Amandla Emoto Ayinhloko(kw) | 90 | 110 |

| Induku yokudla dia. (mm) | 12.5 | 12.5 |

| Ubukhulu. ububanzi bomkhiqizo (mm) | 40 | 30 |

| I-Flat Wire Cross-Sectional | 5-200 | 5 -150 |

| Okukhiphayo(kg/h) | 480 | 800 |

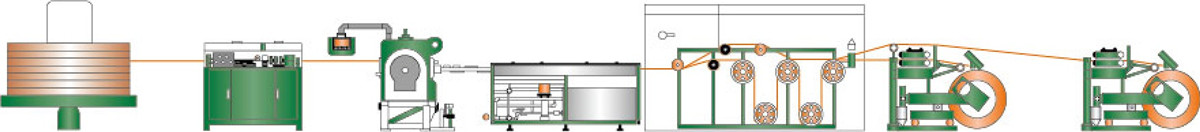

Isakhiwo Solayini Wokukhiqiza

I-Pay-off Pretreatment Extrusion Machine Cooling Sys. Umshini Wokuthatha Umdansi

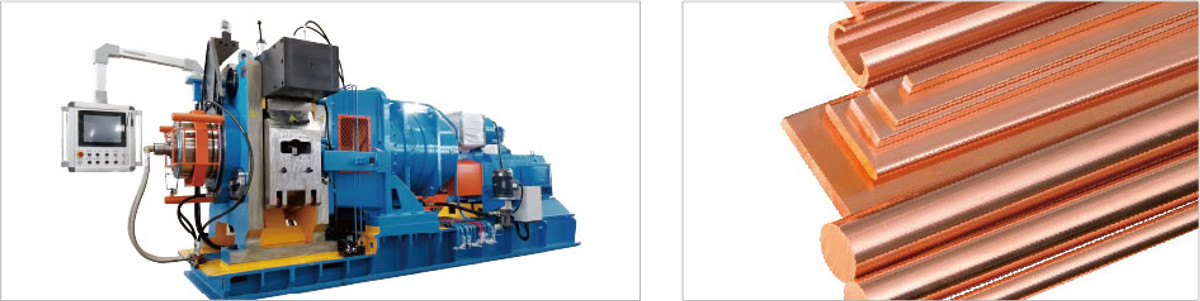

2.Ukwenza i-copper busbar, i-copper round kanye nephrofayili yethusi

| Imodeli | Idatha ye-TLJ350 | I-TLJ 350H | I-TLJ 400 | I-TLJ 400H | I-TLJ 500 | I-TLJ 630 |

| amandla amakhulu emoto (kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| induku yokudla dia. (mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| ubuningi. ububanzi bomkhiqizo (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| i-prod rod dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| indawo ephambanayo yomkhiqizo(mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| okukhiphayo(kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

Isakhiwo Solayini Wokukhiqiza

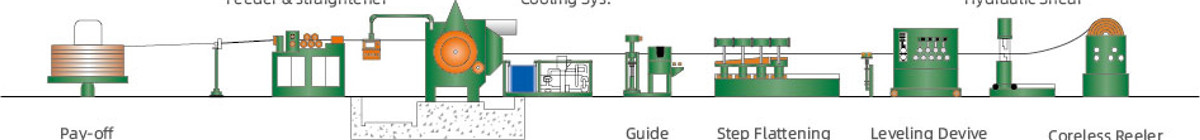

I-Pay-off Feeder & straightener Extrusion Machine Cooling Sys. Umshini Wokuthatha Ibhentshi Lomkhiqizo Wokukhawulela Ubude

3. Ukwenza i-copper busbar, i-copper strip

| Imodeli | I-TLJ 500U | I-TLJ 600U |

| amandla amakhulu emoto (kw) | 355 | 600 |

| induku yokudla dia. (mm) | 20 | 30 |

| ubuningi. ububanzi bomkhiqizo (mm) | 250 | 420 |

| ubuningi. ububanzi kuya ukujiya isilinganiso | 76 | 35 |

| ubukhulu bomkhiqizo(mm) | 3-5 | 14-18 |

| okukhiphayo(kg/h) | 1000 | 3500 |

Isakhiwo Solayini Wokukhiqiza

I-copper alloy induku yokudla

Ukufaka isicelo somqhubi wokuthutha, ithusi elingenalutho, induku yethusi ye-phosphor, umucu wohlaka lomthofu, intambo kaloliwe yokuxhumana njll.

| Idatha ye-TLJ350 | I-TLJ 400 | I-TLJ 500 | I-TLJ 630 | |

| impahla | 1459/62/63/65 brass cu/Ag (AgsO.08%) | ithusi le-phosphor (Pso.5%) cu/Ag (AgsO.3%) | ithusi le-magnesium (MgsO.5%)ithusi lensimbi (Feso.l% | ithusi le-magnesium(MgsO.7%)/Cucrzr |

| induku yokudla dia. (mm) | 12/12.5 | 20 | 20 | 25 |

| ubuningi. ububanzi bomkhiqizo (mm) | 30 | 150 (umugqa wethusi oyisiliva) | 100(umcu wozimele oholayo:) | 320 |

| i-prod rod dia.(mm) | i-phosphor copperball: 10-40 | ithusi le-magnesium: 20-40 | ithusi le-magnesium: 20-40 | |

| okukhiphayo(kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

Isakhiwo Solayini Wokukhiqiza

I-Pay-off Feeder & straightener Extrusion Machine Cooling Sys. Umshini Wokuthatha Wokubamba Ubude

Ukuphakelwa kwezinduku ze-aluminium

Ukufaka isicelo socingo oluyisicaba, ibha yebhasi, kanye ne-conductor enephrofayili, ishubhu eliyindilinga, i-MPE, namashubhu e-PFC

| Imodeli | I-LLJ 300 | I-LLJ 300H | I-LLJ 350 | I-LLJ 400 |

| amandla amakhulu emoto (kw) | 110 | 110 | 160 | 250 |

| induku yokudla dia. (mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| ubuningi. ububanzi bomkhiqizo wocingo oluyisicaba (mm) | 30 | 30 | 170 | |

| I-flat wire product cross-sectional Area(mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| round tube dia. (mm) | 5-20 | 5-20 | 7-50 | |

| ububanzi beshubhu eliyisicaba(mm) | - | ≤40 | ≤70 | |

| intambo eyisicaba/ithubhu Okukhiphayo(kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

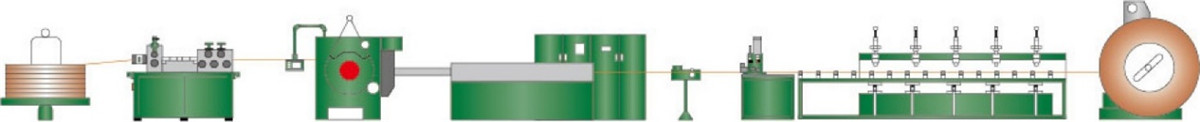

Isakhiwo Solayini Wokukhiqiza

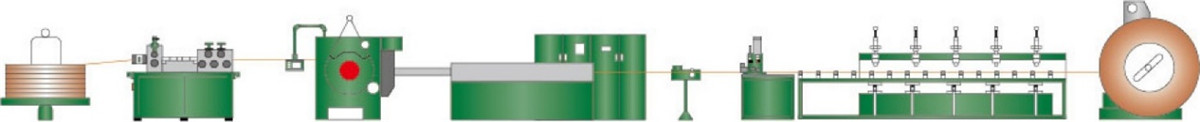

I-pay-off straightener I-Ultrasonic yokuhlanza Umshini Wokuthatha Wokupholisa we-Sys Dancer

Isithombe 217282